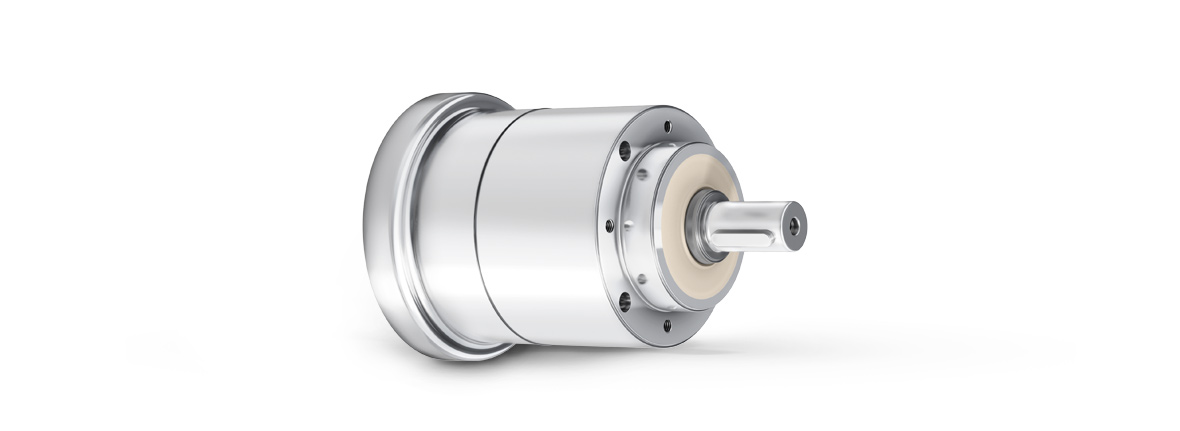

HDV Hygienic Design planetary gearbox

Reliably clean

Low-backlash planetary gearboxes with an output shaft in Hygienic Design. Reliable and efficient cleaning of the gearbox is a key feature of the gearbox series developed in accordance with EHEDG guidelines. The new concept gives designers unprecedented degrees of freedom to develop machines that meet the most exacting requirements for hygienic and sterile production processes.

Downloads

- Technical data / Dimension sheets (884 KB)

- Catalog alpha Basic Line & alpha Value Line (23 MB)

- Mounting kit (174 KB)

- Hygienic Design Brochure (16 MB)

- Ordering code / CAD data HDV

- Operating manual HDV / HDP+ (3 MB)

- Instruction Sheet Hygienic Design (758 KB)

WITTENSTEIN Ltd.

3 The Glades. Festival Way

Stoke on Trent. Staffordshire. ST1 5SQ

Product highlights

Hygienic Design

New design freedom because of direct process integration.

Cleanability

Fast, efficient and reliable cleaning. Resistant to chemical cleaning materials and desinfectants.

Sealing

Optimal sealing properties (IP69X, max. 30 bar)

Reliability

Extremely reliable gearboxes prevent cost-intensive machine breakdowns.

Low maintenance

Highest quality standards guarantee a long service life and extend maintenance intervals.

Certification

- FDA-certified materials

Surface texture

- Smooth-rolled surface made of hygienic steel 1.4404

- Electropolished surface also optionally possible

Cavity-free housing design

- No undercuts

- Large radii

- No horizontal surfaces

Maximum safety

- Triple sealing concept

- Seals resistant to cleaning agents

- IP69X (max. 30 bar)

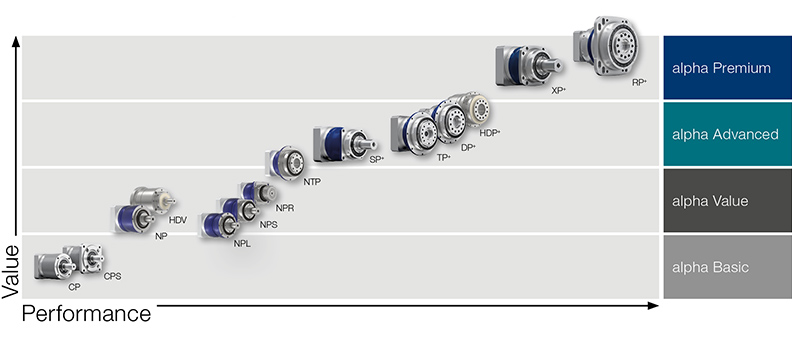

WITTENSTEIN alpha in all axes

Low backlash planetary gearboxes

WITTENSTEIN alpha develops complete, single-supplier solutions for any driving axis. They can be used in virtually any application – from high-precision axes in manufacturing systems to packaging machinery where maximum productivity is required.

The name WITTENSTEIN alpha is a byword for premium quality and reliability, high precision and synchronization accuracy, highest power density, a long lifetime and very simple motor mounting.