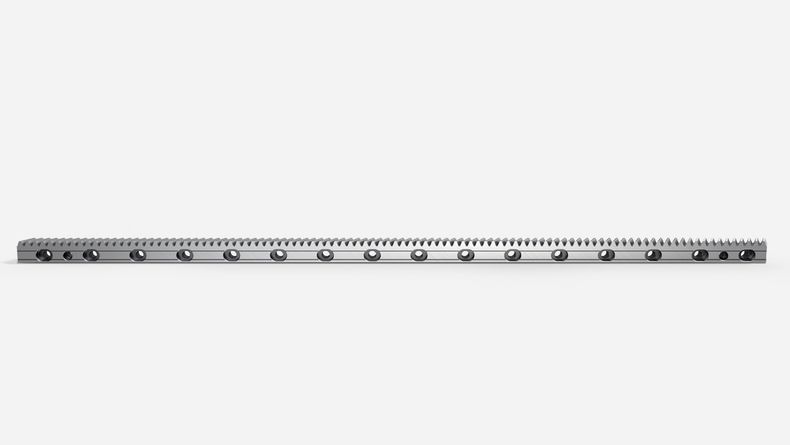

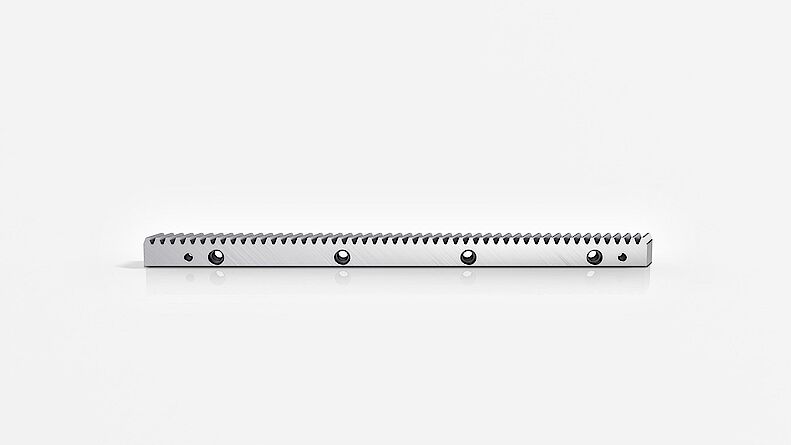

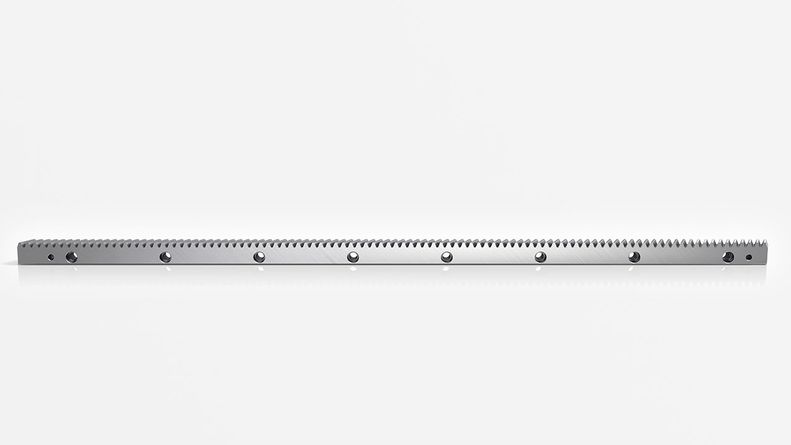

Racks

The suitable rack for every requirement

The correct rack is an essential component in realizing your machine concepts. WITTENSTEIN alpha offers three classes of rack, Premium Class, Value Class and Smart Class, to find the right solution for your application requirements in conjunction with a matched gearbox and pinion.

Rack versions for the system:

- High Performance Class rack - in conjunction with High Performance Lienar System

- INIRA® pining – The revolution in rack assembly

- Premium Class rack - in conjunction with Precision System

- Performance Class rack - in conjunction with Performance Linear System

- Value Class rack - in conjunction with Economy System

Downloads

- INIRA® (4 MB)

- alpha Linear Systems Catalog (20 MB)

- Flyer – alpha Linear Systems (2 MB)

- Operating manual Linear Systems (3 MB)

- Operating manual INIRA® (3 MB)

- Assembly videos alpha Linear Systems

WITTENSTEIN Ltd.

3 The Glades. Festival Way

Stoke on Trent. Staffordshire. ST1 5SQ

Product highlights

Reliability

Fatigue strength sizing of the gearing avoids costly machine downtime

Efficiency

INIRA® enables a significant reduction in assembly time and thus reduces lead times.

Positioning accuracy

Based on the respective requirement, the appropriate variant can be selected for the application.