Mini-AGVs make a big impression with our technology

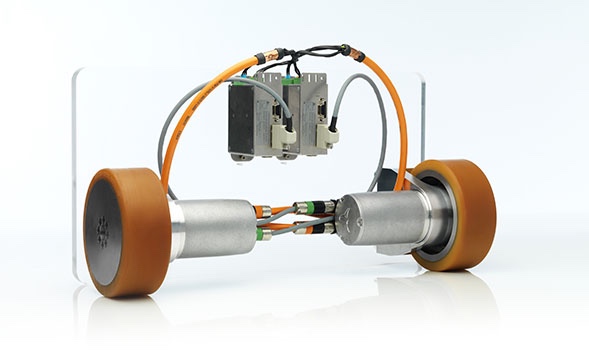

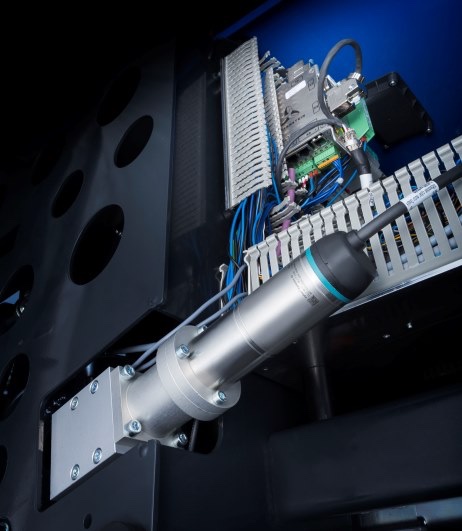

Automated guided vehicle (AGV) systems in miniature – BeeWaTec GmbH is treading new paths with this novel idea. The drive unit is based on WITTENSTEIN's traction drive system (TDS).

AGVs get things moving in intralogistics

AGV systems are used by companies to move goods and materials from A to B. They appear to be able to find their own way: they avoid obstacles and can move forwards, backwards and even sideways. The total weight of each vehicle is between around 300 kilograms and 25 tons. These innovative AGVs are moved by electric drives.

Impressions from the production

Here you can find some film scenes of the FTS in the production with the drive unit which is based on iTAS®.