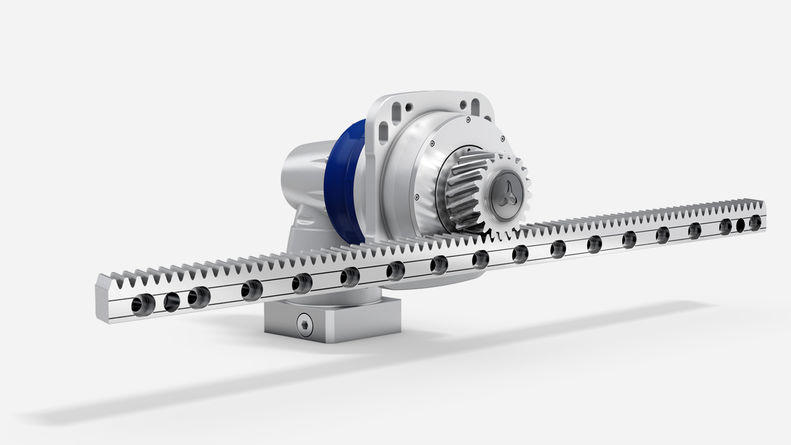

RPC+ bevel gearboxes

High precision and low ratios around the corner

The Premium planetary gearbox RP+, perfect for rack and pinion due to reinforced bearings and a special output interface, are now available in a right-angle version RPC+ with bevel gearing. Gearboxes with bevel gearing are primarily characterized by low gear ratios (ratio 1 and 2) in the right-angle section. Consequently, right-angle and planetary gearhead combinations can achieve the same low ratios as planetary gearboxes. The product design has a positive influence on temperature development in the gearbox and reduces overall heat development in the system as a result. The overall system achieves a higher degree of positioning accuracy as a consequence.

Please contact your respective sales engineer or contact us via mail sales.uk@wittenstein.co.uk for further information or CAD data.

Downloads

WITTENSTEIN Ltd.

3 The Glades. Festival Way

Stoke on Trent. Staffordshire. ST1 5SQ

Product highlights

Consistently high performance

Constant backlash throughout the service life of the gearbox ensures a consistently high performance.

Low maintenance

Highest quality standards guarantee a long service life and extend maintenance intervals.

Machine Interface

Integrated slotted holes ease up the positioning of rack and pinion while increasing the overall system rigidity through the elimination of additional plates.

Forces

Reinforced bearings withstand the highest forces – while maintaining a compact design.

Compactness

The right-angle design allows for shorter machine concepts due to being short in the axial plane.

Positioning accuracy

Minimal backlash and extreme rigidity ensure maximum positioning accuracy at the tool center point.

Reliability

Extremely reliable gearboxes prevent cost-intensive machine breakdowns.

Pinion

The pinion are specially adapted to the gearbox and allow the transmission of extremely high feed forces

Gearbox design

Intelligent design reduces losses to a minimum

Bevel toothing

High-quality bevel toothing with low gear ratios of i = 1 – 2 in the angle section

Temperature development

Low temperature development, even at high speeds

Metal bellows coupling

Metal bellows coupling incorporated for thermal length compensation and protection of the motor bearing

Slotted holes

Integrated slotted holes reduce the design and installation requirements to a minimum

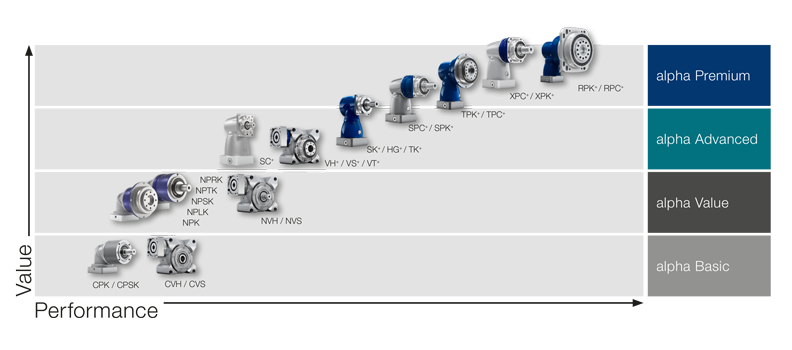

WITTENSTEIN alpha in all axes

Right-angle gearboxes

WITTENSTEIN alpha develops complete, single-supplier solutions for any driving axis. They can be used in virtually any application – from high-precision axes in manufacturing systems to packaging machinery where maximum productivity is required.

The name WITTENSTEIN alpha is a byword for premium quality and reliability, high precision and synchronization accuracy, highest power density, a long lifetime and very simple motor mounting.